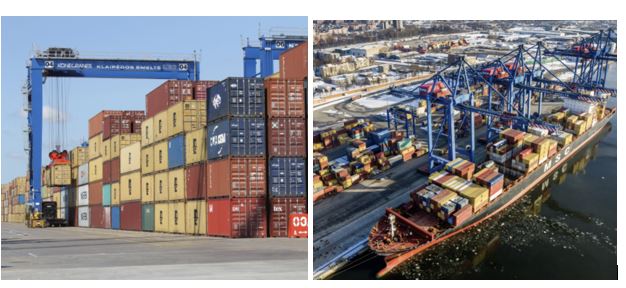

RBS announced the successful deployment of its next-generation Automatic Vessel Planning (AVP) module at Klaipėdos Smeltė Container Terminal, marking a major leap forward in intelligent stowage planning, crane coordination, and terminal-wide operational efficiency.

Within RBS TOPS Expert, AVP version 2 is a high-precision, AI-driven vessel planning engine designed to eliminate traditional planning inefficiencies, including quay crane idle time, excessive re-stows, and quay side congestion.

By predicting workload distribution across quay cranes and synchronizing container availability with real-time yard readiness, AVP ensures each container is picked only once and executed with minimal interference – improving move productivity.

Revolutionizing Vessel Planning

Early deployment results at Klaipėdos Smeltė showcase transformative improvements:

- Planning time reduced by 95+%:

For a vessel carrying over 3,000 full containers, manual planning historically required hours of work, with average times being around 10 or more hours. With AVP, the operation now completes in just 20 seconds. After that the planner will only need a few minutes to check the automated plan and then it is ready to go. - Workforce efficiency more than doubled:

The terminal, which previously required two or more planners per vessel, now operates with one planner capable of managing more vessels simultaneously, and also with higher planning quality. Combined with the time saving above, this is a massive saving for the terminal.

These time and resource efficiencies enable planners to focus on validation, safety, and optimization rather than manual construction of stowage plans.

Quantifiable Terminal Improvements

Just weeks into operation, Klaipėdos Smeltė reports measurable gains, which are slight but will become even more significant in the long-term:

- Quay crane productivity improved to 30+ mph

- 2% reduction in average re-handles in the first weeks

- Reduced vessel berth time

- Higher yard equipment productivity and fewer RTG clashes

The terminal leadership attributes these improvements to AVP’s ability to minimize re-planning, prevent QC idle time, reduce yard re-handlings, and maintain balanced, predictable workloads across equipment fleets.

Terminal Statement: Strong Endorsement from the team

Tadeus Nechviadovic, Head of Planning at Klaipėdos Smeltė Container Terminal, shared his firsthand experience using AVP:

“Yesterday we tested the AVP, and the guys really like that 3000 containers could be planned within 2 minutes… they are really impressed with the functionalities that RBS can provide and everything so far so good.”

Why AVP is Needed for Modern Container Terminals

The AVP module on TOPX introduces a suite of new capabilities designed to enhance accuracy, predictability, and throughput:

- Intelligent Bay & Tier Allocation: AI optimizes packing of tiers using vessel model, weight distribution, crane reach, and segregation rules to create balanced and feasible loading plans.

- Crane Workload Balancing: AVP auto-generates balanced load distribution by bay and QC overlap, preventing bottlenecks and reducing crane interference.

- Consistent Planning Across All Shifts: A centralized TOPX knowledge base ensures planners of all experience levels apply consistent logic and best practices.

- Scenario Simulation (“What-If” Analysis): Planners can simulate multiple operational scenarios in seconds, enabling terminals and carriers to select the optimal strategy for vessel turnaround.

- Reduced Skill Dependency: Junior planners can produce reliable, high-quality plans with minimal supervision, reducing reliance on a limited pool of senior experts.

- Multi-Vessel Planning Coordination: TOPX M88’s multithreaded AVP engine processes plans for multiple vessels in parallel, ensuring smooth coordination during peak operations.

- Increased Terminal Throughput: Optimized stowage, balanced crane operations, and improved yard harmony collectively boost moves per hour—supporting sustained productivity growth.

Concluding thoughts

Overall, Klaipėdos Smeltė reports operational and financial benefits such as:

- Reduced planning time and fewer correction cycles

- Lower QC idle time

- Smoother equipment dispatching and reduced workload spikes

- Fewer yard clashes and reduced RTG utilization costs

- The ability for one planner to manage more vessels at once

These gains demonstrate AVP’s ability not only to streamline operations, but also to significantly enhance terminal productivity and cost efficiency. Ultimately, this technology from RBS will lead to the next generation of intelligent systems that will allow terminals to operate efficiently in this demanding market.

The post RBS TOPS AVP boosts efficiency at Klaipėdos Smeltė Terminal appeared first on Container News.