Walmart is expanding its use of artificial intelligence and IoT technology with a large-scale rollout of Wiliot’s ambient IoT platform, marking one of the biggest deployments of item-level sensing in retail to date.

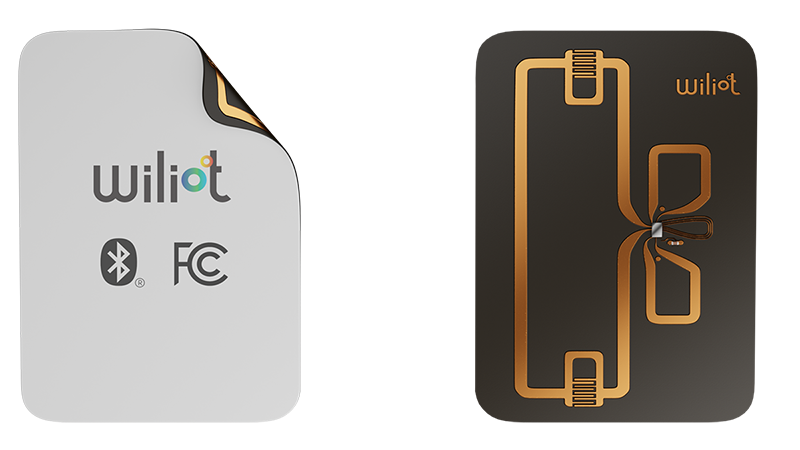

The retail giant is working with Wiliot to apply battery-free Bluetooth sensors, known as “Pixels,” across pallets, packages, and products throughout its network. The devices provide continuous, real-time data on inventory location, movement, and condition, data that’s integrated directly into Walmart’s AI-driven supply chain systems.

Join the leaders shaping freight’s future at

F3: Future of Freight Festival, Oct 21-22.

Network with the industry’s best and discover what’s next.

The technology is already active in more than 500 Walmart locations, including stores and distribution centers. By 2026, the companies expect to expand it to over 4,600 Supercenters, Neighborhood Markets, and logistics hubs, with as many as 90 million sensors in use.

Walmart says the partnership aims to eliminate manual inventory tracking and scanning, two of the most time-consuming and error-prone parts of the retail supply chain. The real-time visibility provided by the sensors could help improve accuracy and efficiency across Walmart’s operations while allowing associates to focus more on customer service.

“Digitization of the supply chain means our associates and systems can make faster, more informed decisions,” said Greg Cathey, Walmart’s senior vice president of transformation and innovation, in a news release. “We’re building a more responsive network that adapts to what’s happening in stores and distribution centers in real time.”

Wiliot’s ambient IoT technology relies on energy-harvesting sensors that communicate wirelessly without the need for batteries. Each Pixel captures data such as temperature, motion, and location, creating a continuous flow of information from product to cloud. That data feeds Walmart’s AI models, which use it to detect anomalies, optimize replenishment, and identify inventory gaps automatically.

Tal Tamir, CEO of Wiliot, said “With Walmart, we are advancing supply chain performance at an unprecedented scale. This nationwide deployment adds a new layer of digitization to Walmart’s supply chain, empowering associates with real-time insights and automation that drive greater efficiency, accuracy, and responsiveness. It’s a testament to the power of ambient IoT and artificial intelligence to help retailers operate smarter, move faster, and deliver stronger outcomes for their business, their associates, and their customers.”

For Wiliot, the Walmart rollout marks a defining step in the adoption of ambient IoT at scale. While the technology has been tested in smaller pilots across retail and logistics, this deployment brings it into one of the world’s largest and most complex supply chains.

Industry analysts see Walmart’s move as a signal that item-level sensing and AI-driven automation are entering a new phase. If the system performs as expected, it could set a precedent for how retailers track goods, manage cold chains, and respond dynamically to supply chain disruptions.

With Wiliot’s technology in place, every item that moves through Walmart’s supply chain will effectively be able to communicate its status, creating what both companies describe as a “living, digital supply chain.”

The post 90 million sensors: Walmart’s bold move in logistics appeared first on FreightWaves.